Showroom

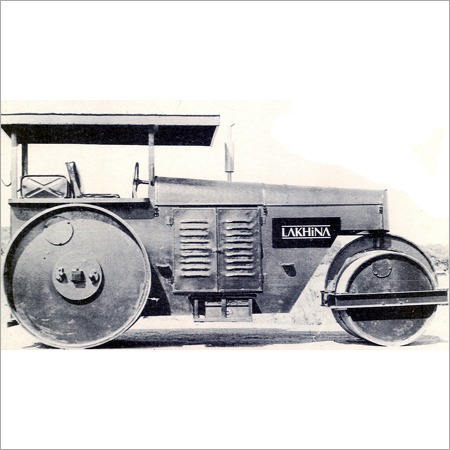

Our company offers wide range of medium to heavy duty Road

Construction Machinery road paving applications to ensure efficient and controlled

operation. Buy from us these heavy engineering vehicles at a reasonable price.

Call us now

08045479396

Our company offers wide range of medium to heavy duty Road

Construction Machinery road paving applications to ensure efficient and controlled

operation. Buy from us these heavy engineering vehicles at a reasonable price.

For an immediate response, please call this

number 08045479396

Price: